Drivetrain

Motors

PimpMyMOD has great source of information on motors. Rates almost all the motors available out there.

All motor specs Don't remember where I got this, but is quite useful. (Let me know if anyone knows where the real link is)

Stock motor has 70 turns. Anything less than about 50 turns require upgraded MOSFETs to prevent burning out the FETs. ASF boards can pretty much use any modified motors.

If you have a stock motor, and want to use an aftermarket motor mount, you have to dril lthe motor. Here is the link on how to do it.

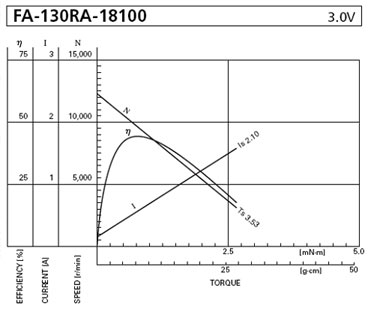

No matter what the motor, if it is stalled, and is given full power, it will likely burn the FETs. As the motor turns, it acts like a generator and puts out a reverse voltage that work against the battery. As a result, less current flow thru the motor. The faster the motor runs, the less current it takes. Obviously, the more efficient the motor work as a generator, the more reverse voltage it puts on the battery which limits the current flowing thru the motor, and therefore the speed. The more winding a motor has, the better it act as a generator. The more powerful the magnet, the better it is at being a generator. A low winding motor is a poor generator, so motor runs faster. However, because it has less winding, it takes more current.

Compilation of motor info: http://users.telenet.be/pintus/Motor_Specs_1.htm

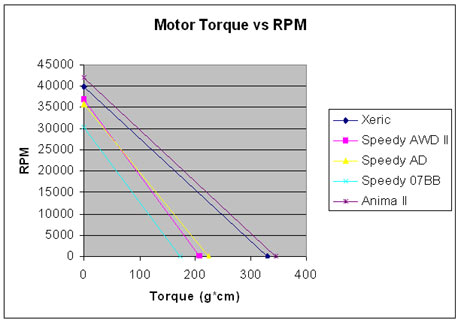

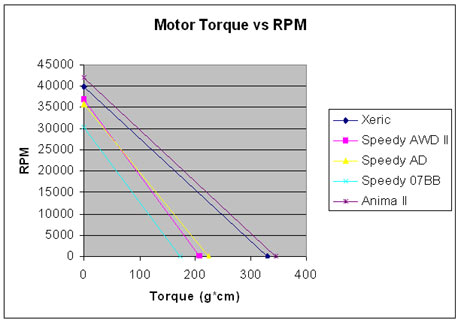

Motor power curves from Atomic Mods: http://www.atomicmods.com/Images/Pages/Motor_Power_Comparison.jpg

Motor power curves calculated from Atomic Mods Curves: http://farm3.static.flickr.com/2165/2483879727_c3eeeb70f6_o.jpg

The PN websites gives some basic motor performance measurements that allow the user to plot out motor performance graph. Electric motors are pretty linear device, so assuming that motor characteristics, one can estimate motor performance if given no load speed, no load current draw, stall torque and stall current draw and testing voltage which I assume to be 4AAA batteries or 4.8V.

Here, a straight line is plotted based on info. given on the PN web page. No load rpm is on the left side where torque generated is 0. At bottom is the stall torque where rpm is 0. Between the two points is an assumed linear line.

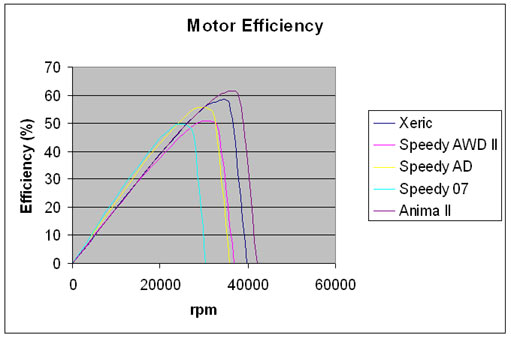

With some more math, efficiency can be calculated. Input power is the voltage times current. Voltage is 4.8V. Current is assumed to go up linearly between no load current and stall current. Output power is torque multiplied by rpm times 2(pi) divided by 531.0448.

Anima II has the lowest number of turns at 33 turns. It also has the highes efficiency. Many factors affect efficiency. In this case, my guess is that lower number of turns means less winding resistance so higher efficiency. All these motors have better efficiency than the basic Mabuchi FA-130 motor has about 45% efficiency.

Gear Ratios

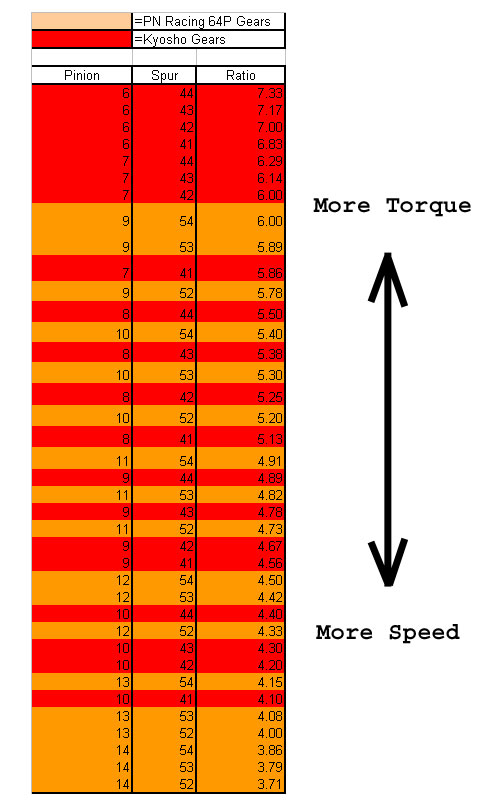

Knowing the torque curves of the motors, the best way to take advantage of it is to use different gear ratios. This is a gear ratio chart comparing stock gears with the 64 pitch gears. Starting with the highest ratio at the top and lowest at the bottom. Kyosho gears are the ones that came with mini-z. The spur is 44T, and pinion is 6-9T. 64 pitch is a new gear developed by PN to give more ratio choices.

It use to be that the standard recommendation is use 9 teeth pinion for stock and 10 for modified along with the standard 44T diff. As racers learn to make best use of motor, now, the recommendation is the reverse. The stock motor has more winding, hence more low end torque. Therefore, use higher gearing for stock motors. Modified motor on the other hand, usually have less winding, and spins faster. To make maximum use of the faster rev, use a smaller pinion for modified. Especially ones that advertise high revs. Hence, the new recommendation is to use 4.9 or so ratio for modified and about 4.3 ratio for stock. You can look at the chart below to find gear combinations that will give the desired ratios. The 6 and 7 teeth with stock 44T spur will give longer battery life, but are too slow.

Motor Pinions

After running the car for a while, you will find that the pinion gear on the motor wears out quite fast. For me, for a modified car, after couple of battery charges, the nice silky fast silent running is gone even with the delrin pinion. About 10 battery changes latter, the gears starts to make slightly more noise. After maybe 30 runs, there is noticable wear on the pinion and significant noise. There is also some drag in the drivetrain as the pinion wears down.

However, one thing to note, and this is very important is that none of these standard pinions match the gear on the diff. You read that right, all the standard pinion is a .5 module pitch. The diff use a non standard gear pitch. Kyosho made a mistake on the gears on mini-z. Think the reason is Kyosho wanted the diff gear to be small to give more ground clearance, so they used a modified .5 module pitch on the diff for more clearance. That is the reason pinions wear so fast. The gears do not match properly. The HPI gear will last the longest because is made of steel, but the problem is still with the mismatch gear pitch.

Thanks to PN Racing, they came up with pro match pinion gears so the pitch on pro match pinon matches the pitch on the diff gear. PN also has 64 pitch gears. The finer pitch allow for wider range of gear ratio adjustment. Is a no brainer, for a couple dollars, the first thing you should get is the pro match pinion.

For more investment, the PN 64 pitch geat is even better, but if you go with 64 pitch gear, you have to change both the diff gear and the pinion together. The 64 pitch gear only fit a ball diff, so you will need a ball diff for the 64 pitch. The 64 pitch also have a different motor shaft to diff spacing, so the stock plastic motor mount may not have enough adjustment with the plastic shims to achieve the correct gear teeth engagement with certain ratios. In that case, it will be necessary to get an aluminum motor mount also that will allow you to adjust the motor position with 2 screws.

http://www.engineersedge.com/gear_pitch_chart.htm